High Strength Vertical Shaft Impact Crusher Machine 50mm Max

Feeding Size

Product Description

Impact crusher, abbreviated as impact crusher, commonly known as sand maker, is

an internationally advanced high energy and low consumption impact

crusher. Its performance plays an irreplaceable role in various ore

fine crushing equipment and is currently the best Effective,

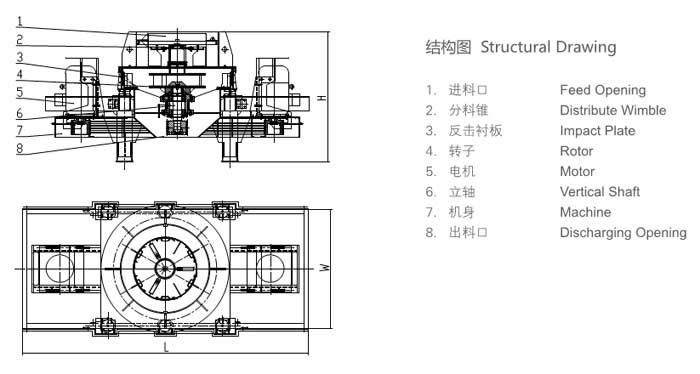

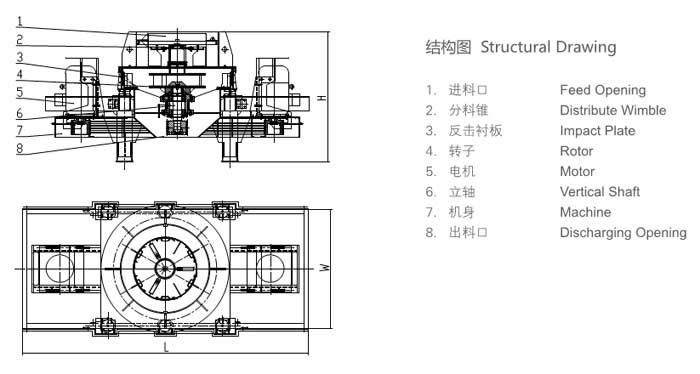

practical and reliable stone crushing machine. The vertical shaft

impact crusher consists of seven parts: feed, distributor, vortex

crushing chamber, impeller experience, main shaft assembly, base

transmission and motor. It is widely used for fine crushing and coarse grinding of metal and non

metal ores, cement, refractory material, grinding material, glass

raw material, building aggregates, artificial sand and all kinds of

metallurgical slags. It is especially suitable for medium hardness

materials, high hardness materials and corrosion resistance

materials, such as carborundum, emery, magnesia etc.

Application

1. Pebble, Rock( the limestone, granite, basalt, aluminum,

andesite, etc.), Ore tailings, Attle artificial sand production.

2. Building aggregate, highway, cushion, asphalt concrete and

cement aggregate production.

3. Sand making production and stone reshaping production in water

conservancy and hydropower engineering

field,highway,railway,bridge,passenger line,airport

runway,municipal engineering and high-rise buildings.

4. The grinding anterior finely process of mining areas. Building

materials, mining, metallurgy, hemical industry, cement, abrasive,

refractory material, etc.

5. The crush of high abrasive materials resistance and secondary

disassembly, desulphuration of thermal power and metallurgy, slag

and construction waste.

6. The production of glass,quartz sand and other high purity

material.

Main Parameters

| Model | Max feeding size (mm) | Power (Kw) | Rotation speed (r/min) | Capacity (t/h) | Dimension (mm) | Total weight (including motor) (t) |

| PCL-600 | 30 | 2×30 | 2000-3000 | 12-30 | 2800×Ф1550×2030 | 5.6 |

| PCL-750 | 35 | 2×45 | 1500-2500 | 25-55 | 3300×Ф1800×2440 | 7.3 |

| PCL-900A | 40 | 2×55 | 1200-2000 | 55-100 | 3750×Ф2120×2660 | 12.1 |

| PCL-900B | 40 | 2×75 | 1000-1450 | 65-130 | 3750×Ф2300×2090 | 13.6 |

| PCL-1050 | 45 | 2×(90-110) | 1000-1700 | 100-160 | 4480×Ф2450×3906 | 16.9 |

| PCL-1250 | 45 | 2×(132-180) | 850-1450 | 160-300 | 4563×Ф2650×3716 | 22 |

| PCL-1350 | 50 | 2×(180-220) | 800-1193 | 200-360 | 5340×Ф2940×3650 | 26 |

Main Advantages

- Novel structure, unique and balanced operation.

- Small energy consumption, high output and large crushing ratio.

- The equipment is small in size, easy to operate, and easy to

install and maintain.

- A small number of wear-resistant parts are made of extra hard

wear-resistant materials, small size, light weight, easy to replace

accessories.

- Large capacity, stable running, high-efficiency.

Field Usage